Supply chain transformation is on everyone’s radar right now, and with good reason. Now is a great time to examine the hub and spoke supply chain network model. It’s an intuitive approach to a transformation program, and one ideally suited to multinational organizations looking to enhance efficiency and resilience across far-flung locations.

A supply chain transformation is not for the faint of heart

Supply chains – and their reliability – have never been more prominent. Brought to the fore by the coronavirus pandemic, ongoing supply chain disruptions continue to affect the business environment and the lives of people all over the world, needing everything from macaroni and cheese to lawn mowers. In coping with today’s all-too-common disruptions, your company would benefit from an integrated business transformation plan.

Putting together a comprehensive plan is a daunting project. A program for transformation needs to incorporate all aspects of your business. Sales plans, financial plans, strategic and tactical supply chain plans – it’s a big ask. Understandably, your supply chain team may be staring the task down with a wary eye.

Making the transformation work for groups with differing priorities

Implementing a supply chain transformation will comprise multiple rounds of blueprinting, building, and testing, to be followed by eventual deployment. The key deliverables for blueprinting are those core business requirements and processes that need to be put in place. The common challenge in producing these is the persistent complexity of the process that arises from the often-conflicting requirements of multiple business interests within an organization. This is especially true of large, multinational companies whose divisions often come to the table with diverging or competing priorities.

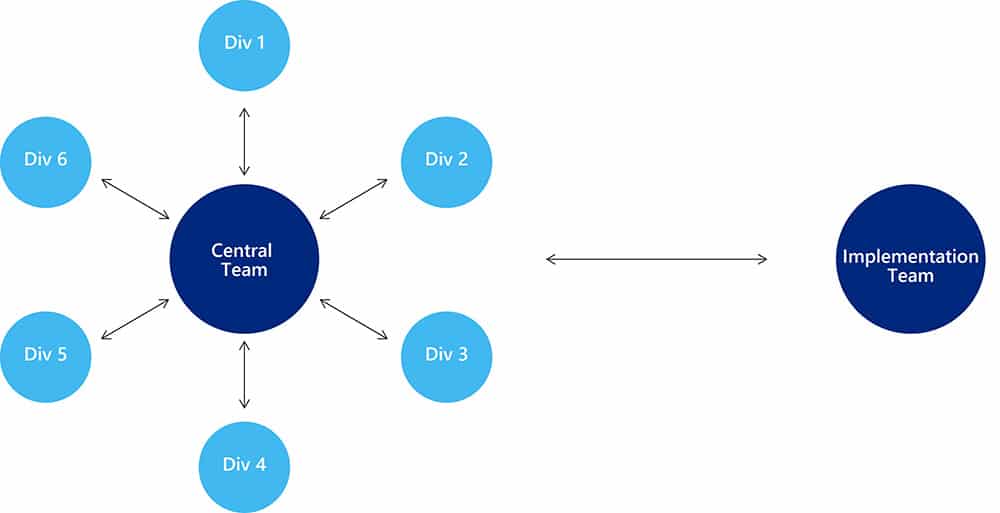

Under conditions such as these, the back-and-forth on requirements can seem interminable. We’ve found that the hub and spoke network model is an effective approach to dealing with these impasses. The hub and spoke distribution method involves a central location. All requirements either begin at this hub or are received by the hub for further distribution to other company-owned facilities called “spokes.” The inherent flexibility in this arrangement makes it easier to address the various priorities of different corporate stakeholders.

The hub works with the spokes collectively for superior efficiency

In the diagram above, we refer to the hub as a “central team.” Consisting of subject matter experts (SMEs), the hub drives conversation with the organization’s many divisions – represented by the spokes. The central team works to make sure that they properly address all the requirements brought by the spokes in the most effective way.

In traditional point-to-point models, the implementation team usually works with the SMEs from assorted divisions within the organization, either concurrently or in sequence. This standard approach can be quite cumbersome. Gathering all requirements from the divisions involved often consumes a considerable amount of time and effort.

The central team and its SMEs understand the overall needs of the organization. There is also a high probability that, within the SMEs, there is detailed knowledge of the needs of several of the company’s divisions.

Overlapping and contradicting requirements (or a combination of both) is a built-in risk of the point-to-point model. That’s why – in the hub and spoke approach – the central team in the hub works collaboratively with all the divisions in each spoke. It reduces the length of the iterative process that determines the sum of the requirements for the entire network.

Core benefits of the hub and spoke method:

1. The central team can separate authentic needs from the noise and thus address the significant business requirements that are essential to the organization.

2. A central team allows the implementation team (SI) to focus on designing solutions based on best practices. The SI team won’t entangle themselves in the internal politics between the divisions of a multinational corporation.

3. A central team can gather business requirements in a timely fashion, allowing implementation to be completed as soon as possible.

The hub and spoke in practice

In a past engagement, we worked with a client to apply the hub and spoke approach as part of a transformation program for a multinational organization. They had five large divisions across Asia, Europe, and North and South America. The project was a crucial strategic driver for the entire company. Using hub and spoke, and making use of its intrinsic advantages, we completed implementation on schedule.

Collectively, we showed that the method facilitates centralized processing and due deliberation on business requirements. The process reduced back-and-forth and focused attention purely on the potential benefits to the organization. The central team was an equal champion of all divisions and regions, with the goal of deeper understanding of their shared needs and challenges. This made them all the more willing to come together on a converging set of requirements and plans.

Author: Darsono Tjokroamidjojo, Ph.D., PMP, PMI-ACP, Director NTT Data Supply Chain Consulting

Reach out to us and learn how NTT DATA Supply Chain Consulting will help get your organization working together and on to implementation. Our top supply chain talent, enabled by proven, leading-edge digital assets – tools, methods, and content – deliver actionable insights and measurable outcomes to some of today’s largest and most complex supply chains.